FG-Catalog Fiberglass Ƙarfi kuma Samfuran Fiberglass mai nauyi

FIBERGLASS YARN

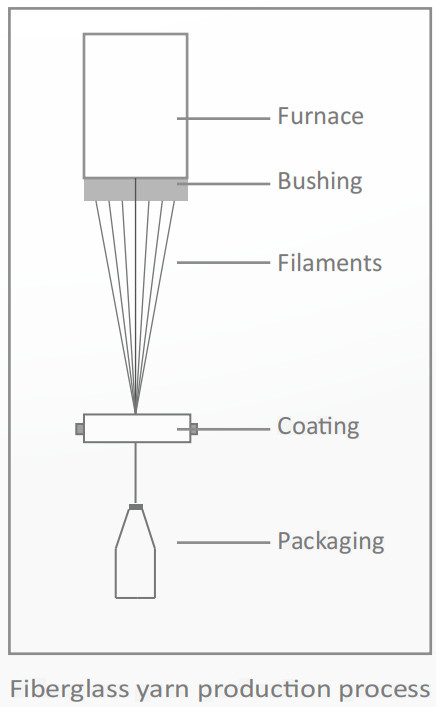

Tsarin canza gilashin da aka narke zuwa zaruruwa ta hanyar zafi da zana gilashin zuwa filaye masu kyau an san shi shekaru da yawa;duk da haka, bayan ci gaban masana'antu a cikin shekarun 1930s sun ba da damar samar da yawan samfuran waɗannan samfuran waɗanda suka dace da kayan aikin yadi.

Ana samun zaɓukan ta hanyar matakai biyar da aka sani da batching, narkewa, fiberizaton, sutura da bushewa/marufi.

•Batching

A lokacin wannan mataki, ana auna kayan da aka yi a hankali daidai gwargwado kuma an gauraye su sosai ko kuma a daɗe.Misali, E-Glass, SiO2 (Silica), Al2O3 (aluminium oxide), CaO (calcium oxide ko lemun tsami), MgO (magnesium oxide), B2O3 (boron oxide), da sauransu…

•Narke

Da zarar an daidaita kayan sai a aika zuwa tanderu na musamman tare da zafin jiki na kusan 1400 ° C.Yawanci ana kasu tanderu zuwa sassa uku tare da kewayon zafin jiki daban-daban.

• Fiberizaton

Gilashin da aka narkar da shi ya ratsa ta cikin daji da aka yi da gawawwakin platnum mai jurewa tare da ƙayyadaddun adadin fitattun filaye masu kyau.Jiragen sama na ruwa suna kwantar da filaye yayin da suke fitowa daga cikin daji kuma ana tattara su a jere ta hanyar manyan iska.Tunda an sanya tashin hankali a nan ana zana rafin gilashin narkakkar zuwa cikin filaye masu bakin ciki.

•Coatng

Ana amfani da suturar sinadarai akan filaye don aiki azaman mai mai.Wannan matakin yana da mahimmanci don kare fitilun daga ɓarna da wargajewa yayin da ake tattara su kuma ana raunata su zuwa ƙirƙirar fakiti.

•Bushewa/Marufi

Ana tattara filayen da aka zana tare a cikin damfi, suna samar da igiyar gilashi wanda ya ƙunshi nau'ikan filaye daban-daban.An raunata igiyar a kan ganga a cikin kunshin kafa wanda yayi kama da zaren zare.

YARN NOMENCLATURE

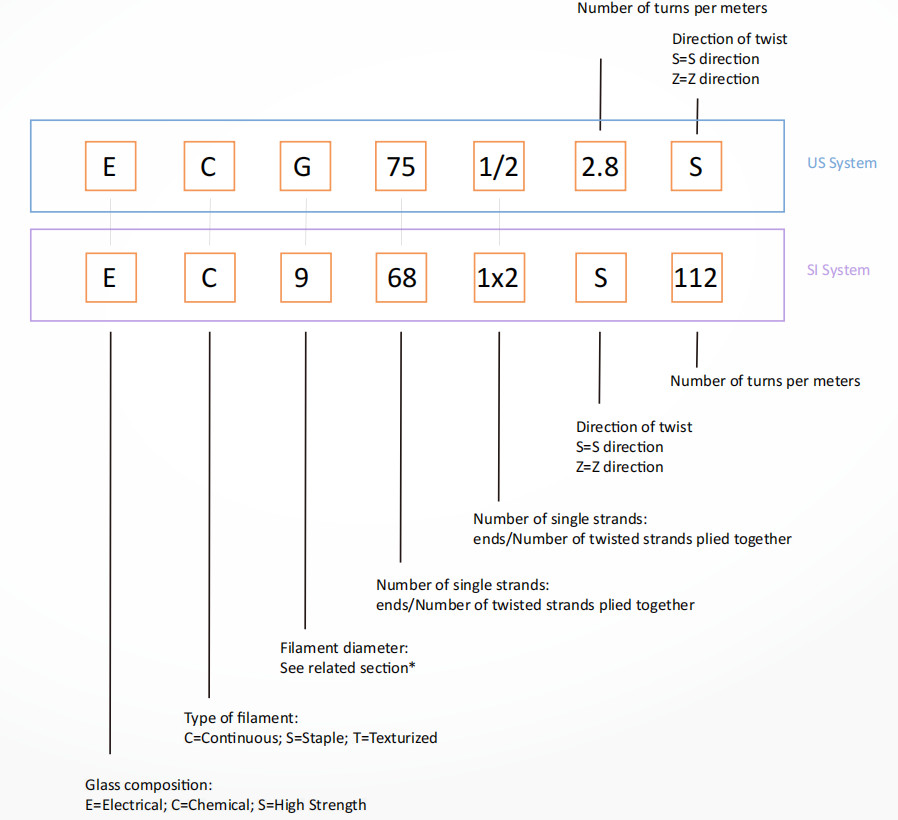

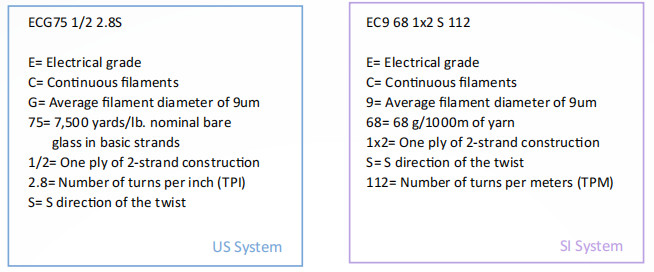

Ana gano filayen gilashin ko dai ta tsarin al'adar Amurka (tsarin inch-pound) ko ta tsarin SI/metric (tsarin TEX/metric).Dukansu an san ma'aunin ma'auni ne a cikin ƙasa waɗanda ke gano nau'in gilashin gilashi, nau'in filament, ƙidayar igiya da ginin yarn.

A ƙasa akwai takamaiman tsarin identficaton na ƙa'idodi biyu:

YARN NOMENCLATURE (ci gaba)

Misalai na tsarin identficaton yarn

karkatar da kai tsaye

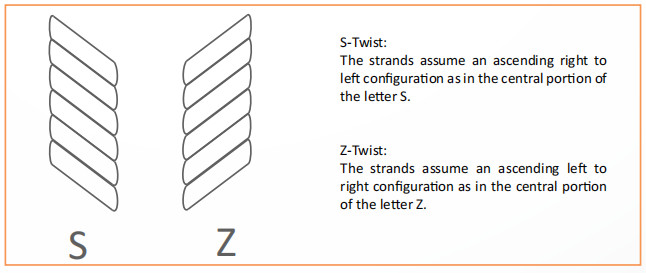

Ana amfani da jujjuyawar da injina zuwa yadudduka don samar da fa'idodi dangane da ingantacciyar juriya, aiki mai kyau, da ƙarfin ƙarfi mai ƙarfi.Madaidaicin karkarwa yawanci ana nunawa ko dai tare da harafin S ko Z.

Za'a iya gane jagorar S ko Z na zaren ta gangaren zaren lokacin da aka riƙe ta a madaidaicin positon.

YARN NOMENCLATURE (ci gaba)

Diamita na Yarn - Kwatanta dabi'u tsakanin tsarin Amurka da SI

| Rukunin Amurka (wasika) | SI Units(microns) | SI UnitsTEX (g/100m) | Kimanin Adadin Filaments |

| BC | 4 | 1.7 | 51 |

| BC | 4 | 2.2 | 66 |

| BC | 4 | 3.3 | 102 |

| D | 5 | 2.75 | 51 |

| C | 4.5 | 4.1 | 102 |

| D | 5 | 5.5 | 102 |

| D | 5 | 11 | 204 |

| E | 7 | 22 | 204 |

| BC | 4 | 33 | 1064 |

| DE | 6 | 33 | 408 |

| G | 9 | 33 | 204 |

| E | 7 | 45 | 408 |

| H | 11 | 45 | 204 |

| DE | 6 | 50 | 612 |

| DE | 6 | 66 | 816 |

| G | 9 | 66 | 408 |

| K | 13 | 66 | 204 |

| H | 11 | 90 | 408 |

| DE | 6 | 99 | 1224 |

| DE | 6 | 134 | 1632 |

| G | 9 | 134 | 816 |

| K | 13 | 134 | 408 |

| H | 11 | 198 | 816 |

| G | 9 | 257 | 1632 |

| K | 13 | 275 | 816 |

| H | 11 | 275 | 1224 |

Ƙimar kwatanta - Strand Twist

| TPI | TPM | TPI | TPM |

| 0.5 | 20 | 3.0 | 120 |

| 0.7 | 28 | 3.5 | 140 |

| 1.0 | 40 | 3.8 | 152 |

| 1.3 | 52 | 4.0 | 162 |

| 2.0 | 80 | 5.0 | 200 |

| 2.8 | 112 | 7.0 | 280 |

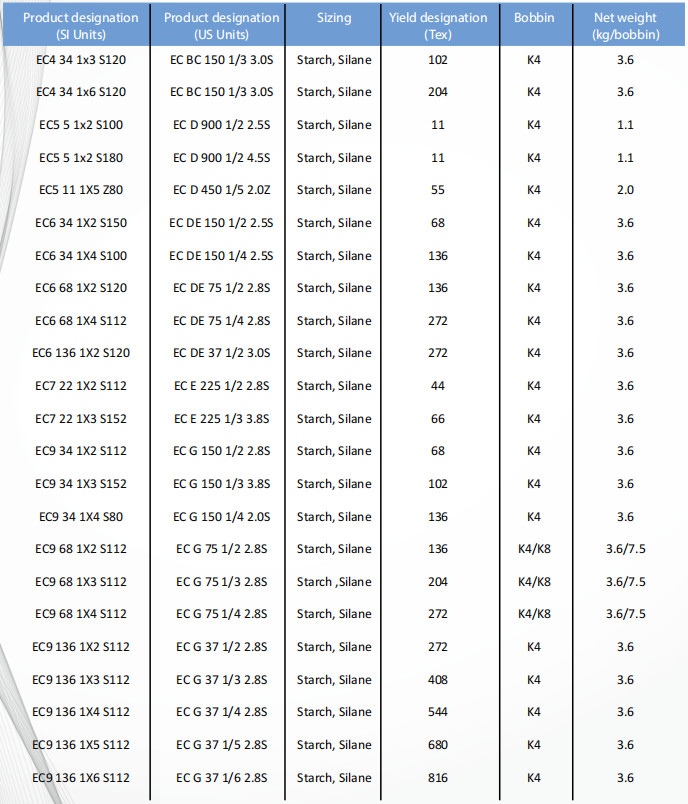

YARNS

E-Glass Ci gaba da murɗaɗɗen yarn

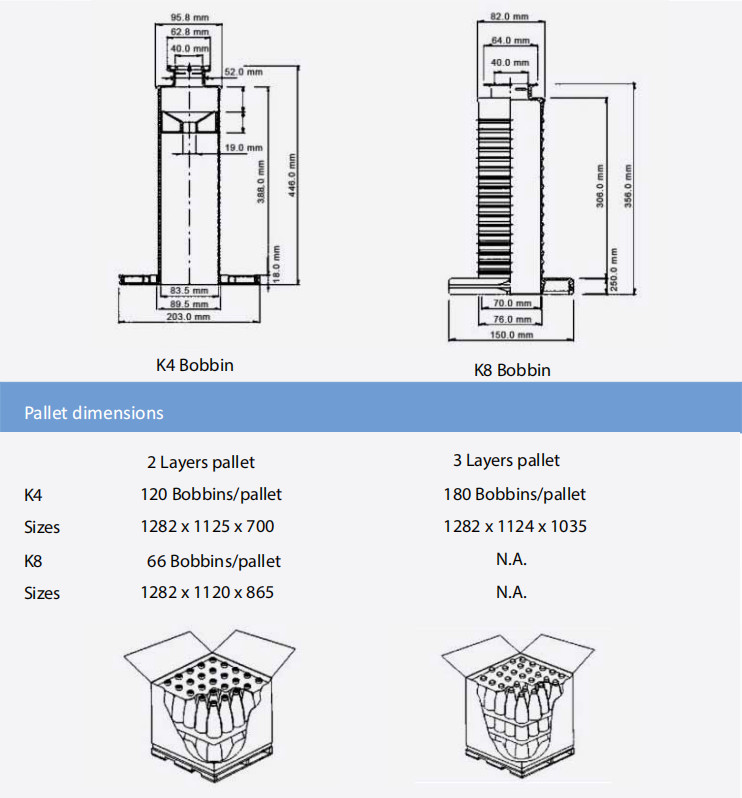

Marufi

E-Glass Ci gaba da murɗaɗɗen yarn